Digitalization – Schubs plays a pioneering role

in the digital world of switchboard manufacturing

Roboschalt

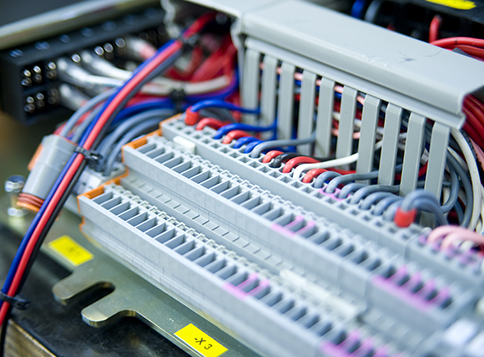

On the 1st of July 2018 the foundation for a research partnership was laid between the Ruhr-University Bochum and Schubs. The research was initially set up for two years and is funded by the Federal Ministry of Economics and Technology (BMWi) within the framework of the “central program for innovation in medium-sized companies”. The project goal is to design a solution to automate the combining of wiring in the control cabinet, consisting of a cable compartment and an assembly-tool, with a program-based robot. Due to the almost unlimited variety in type, size and individual production count (batch size 1), globally, no solution was yet found.

Our main focus is to establish and combine a so-called cyber-physical system (CPS), combining elements like mobile facilities, stationary machines, plants and robots to coordinate all linked physical actions among themselves. Via a user interface the system is still accessible for personnel to manage changes, configurations and to retrieve information of the workflow. In the near future RoboSchalt will be a substantial contributor to efficiency in terms of work safety and speed, reducing costs and the ability to execute complex processes faster.

DAKoTA (word-for-word translation from German to English: Digital Coworker Technology Working Station)

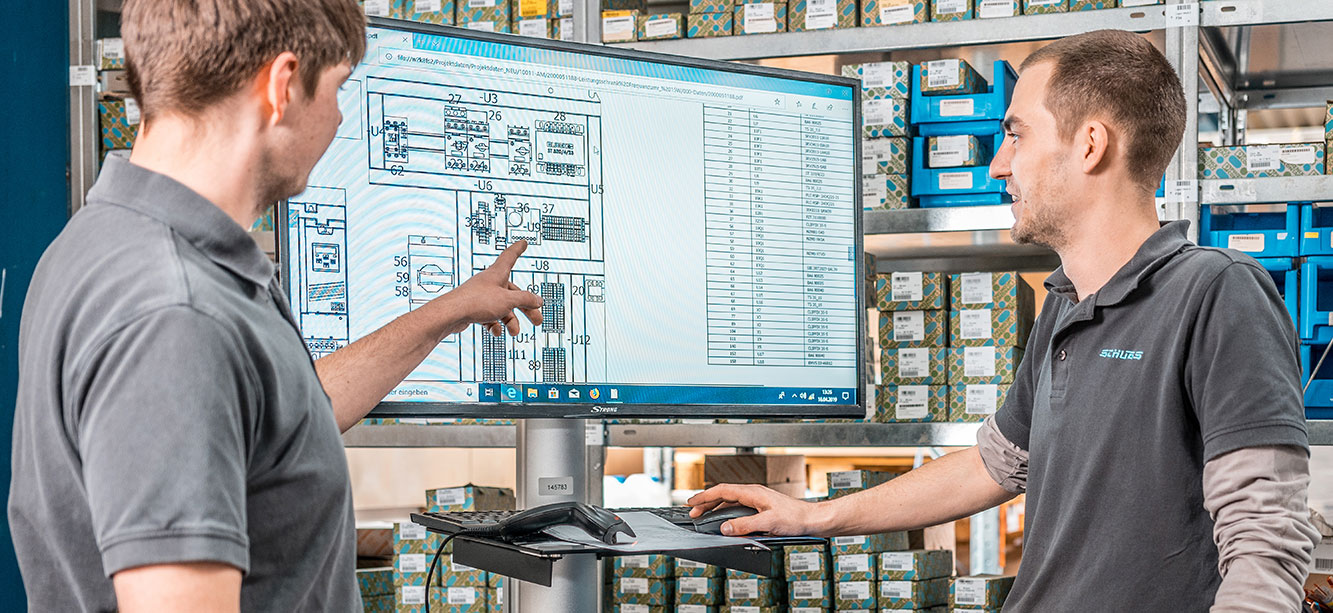

For the complete internal use, we developed a data processing-solution. DAKoTA is especially suitable for individual, small batch and series production for multiple-unit products and on the behalf of customers. The modular design and the open architecture ensure an industry-specific customization, which was successfully implemented in customer projects comprising steel and plant construction, automobile industry, machine construction, mechanical engineering, electrical engineering and other industries.

The module DAKoTA provides efficient production of manufactured goods with a consistent serial production of the same structure. The module is divided in 4 areas which contain various information: head mask, project data, component pictures, a bill of material, picture upload and workflow. Based on the modular structure, individual customizing and adaptation to the needs of our customers are possible. Additionally, standard functions can be extended for each individual project.

DAKoTA has many benefits. Due to the paperless equipping of assembly plates, storage room formerly used is now available for new production plants. The identification of components is even simpler because of scannable coding and leads to intuitive operation from several computers at the same time. This facilitates engaging unskilled employees or people with disabilities. Dakota is established at the welfare institutions as well.

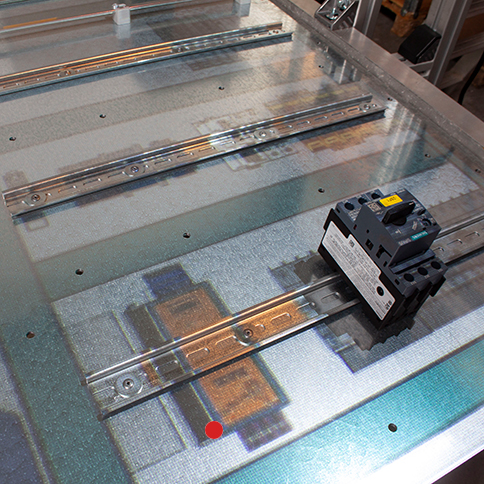

Moonshiner

Visuelle Assistenzsysteme wie Moonshiner sind ein großer Fortschritt im Produktionsalltag und der Vielfältigkeit der Schaltschranktechnik. Sie sparen Zeit und verhindern Produktionsausfälle, beziehungsweise eine hohe Ausschussrate. Diese Unterstützung wird auch ‚Augmented Reality‘ genannt, darunter versteht man die computergestützte Erweiterung der Realitätswahrnehmung. So können sich Mitarbeiter während des Arbeitsprozesses sowohl das Layout, Stückliste als auch vorher gedruckten Labels für die Bauteile auf der Montagefläche mittels Projektion anzeigen lassen und somit die reale Montagesituation mit digitalen Bauplänen abgleichen. Die Bauteile wurden hierfür bereits vorab kommissioniert. Systematisch wird Moonshiner von einem ERP-System und CAE-System mit der Verwaltung von diversen Daten wie Artikel- und Bilddaten, Artikelnummern, EAN-Codes und Betriebsmittelkennzeichnungen unterstützt.